Mitsubishi Air Conditioner Error Codes | Troubleshooting Guide

Mitsubishi air conditioners are known for their high-quality performance and durability, but like any other appliance, they can experience issues over time. Here are the Mitsubishi air conditioner error codes that can help identify and fix common problems that may arise.

This guide will provide an overview of the common issues with Mitsubishi air conditioners, such as issues with the unit not turning on or producing cold air, unusual noises, or leaks. It will also offer some basic troubleshooting steps that users can take to diagnose and potentially solve these issues.

It is important to note that while some problems can be fixed easily by following simple troubleshooting steps, other issues may require professional assistance. Users should exercise caution when attempting to diagnose or repair their air conditioner and seek professional help. Overall, this Mitsubishi air conditioner error codes list can be useful for anyone who owns a Mitsubishi air conditioner and wants to ensure it operates effectively and efficiently.

Table of Contents

Mitsubishi AC Troubleshooting Guide

Please carry out the following checks before making a service call.

Models: DXK09Z5L-S, DXK12Z5L-S, DXK15Z5L-S

The air-conditioner does not work at all.

- Has the power switch been turned off?

- Has the timer been set in the “ON” position?

- Is there a power failure or a blown fuse?

Poor cooling or heating

- Have you set the thermostat at a suitable temperature?

- Is the air filter clean? (Not clogged?)

- Did you leave any doors or windows open?

Poor cooling

- Is there any direct sunlight entering the room?

- Is there a heat source in the room?

- Are there too many people in the room?

Models: SRK63ZM-S, SRK71ZM-S, SRK80ZM-S

Mitsubishi Air Conditioner Error Codes Complete List

Mitsubishi “E” Error Codes

| Code Text | Description | Cause | Check Procedure |

| E2 Error | Remote controller transmitting error. | Incorrect wiring of remote or incorrect dip switch setting if units are grouped. | Check unit addressing if grouped or check remote is only wired to the master indoor unit. |

| E4 Error | Remote controller transmitting error. | Incorrect wiring of remote or incorrect dip switch setting if units are grouped. | Check unit addressing if grouped or check remote is only wired to the master indoor unit. |

| E0 Error | Remote controller transmitting error. | Incorrect wiring of remote or incorrect dip switch setting if units are grouped. | Check unit addressing if grouped or check remote is only wired to the master indoor unit. |

| E5 Error | Remote controller communication/receiving an error. | The remote controller is incorrectly wired or the controller does not have the correct 12vdc supply.

Incorrect settings on SW1 switches at the outdoor unit. |

Check for 12vdc down to the controller and make sure LED 2 is lit on the FTC board.

Check the SW1 dip switches on the outdoor unit are set correctly. |

| E4 Error | Remote controller communication/receiving an error. | The remote controller is incorrectly wired or the controller does not have the correct 12vdc supply.

Incorrect settings on SW1 switches at the outdoor unit. |

Check for 12vdc down to the controller and make sure LED 2 is lit on the FTC board.

Check the SW1 dip switches on the outdoor unit are set correctly. |

| E8 Error | Comms Failure indoor to outdoor (S2/S3) | Mis-wiring of indoor to outdoor cable. The system powered up incorrectly. | Check for pumps wired in, Check the indoor isolator, and Repower in the correct sequence i.e. indoor than outdoor. |

| E9 Error | Comms Failure indoor to outdoor (S2/S3) | Mis-wiring of indoor to outdoor cable. The system powered up incorrectly. | Check for pumps wired in, Check the indoor isolator, and Repower in the correct sequence i.e. indoor than outdoor. |

| EF Error | Non-defined error code. | Noise interference. | Power down the system for 30 seconds and then switch back on. |

| E3 Error | Remote controller transmitting error. | Incorrect wiring of remote or incorrect dip switch setting if units are grouped. | Check unit addressing if grouped or check remote is only wired to the master indoor unit. |

| EA Error | Miswiring/communication error when more than 1 unit is connected in a group. | Miswiring/lose interconnecting cables. Noise interference. More than 1 unit in the same group is set as a master (address 0). | Check the wiring of interconnecting cables. Check master and slave addressing when more than 1 unit is connected in a group. |

Mitsubishi “A” Error Codes

| Code Text | Description | Cause |

Check Procedure |

| FA Error | 51CM connector open circuit. | A thermal relay is an open circuit | Check the thermal relay for disconnection or contact failure, possible defective board |

| A6 Error | Communication error with communication processor. | Lossnay address not transmitted. | Check M-Net voltage. |

| PA Error | Drain Fault.

The indoor unit detects high condensate levels before the unit has started running. |

Float switch activated by high water level. If the unit has a drain sensor then the resistance of the drain sensor has changed due to being immersed in water. | Check the water level in the drip tray – If full, then check drain pump operation, blockage in the drain pipe, and/or sludge or debris in the drip tray blocking the drain pump intake.

If the drip tray is empty, investigate why the unit believes it is full of water. Test the float switch for correct movement and measure continuity through the switch – open contact when OK and closed contact when in alarm. If the unit has a drain sensor instead of a float then test for correct resistance. Also, a check fault has not been generated from an external high-limit switch connected to either CN4F or CN31 on the indoor board. |

| A3 Error | The transmission line is busy when Mr.Slim is connected to the M-Net transmission line. | No data could be transmitted for 8 minutes. | Check A-MNET connections (TB7). |

| EA Error | Miswiring/communication error when more than 1 unit is connected in a group. | Miswiring/lose interconnecting cables. Noise interference. More than 1 unit in the same group is set as a master (address 0). | Check the wiring of interconnecting cables. Check master and slave addressing when more than 1 unit is connected in a group. |

| A0 Error | Duplicate address. | Units are attached with the same address. | Change the address and reset the unit’s power. |

| A7 Error | Communication error. A-Mnet wiring, range of transmission wiring exceeded, faulty A-MNET converter | A-Mnet wiring, range of transmission wiring exceeded incorrect M-net address setting, faulty A-Mnet converter. | Test M-net wiring. or Test M-net transmission voltage. Test the M-net address setting. Replace the A-Mnet converter. |

| A8 Error | M-Net no response/communication error. | The range of transmission wiring exceeded the faulty A-Mnet converter, the incorrect wire used for the Mnet connection. | Check A-Mnet wiring, cable type should be 2-core screened CY cable, 1.5mm. |

| EA Error | Communication fault between Indoor FTC and Outdoor Ecodan | Mis-wiring between indoor and outdoor on S1-S2-S3, power supply issue, or blown fuse | Check the voltage on interconnecting cable on S1-S2-S3, check 240v supply to indoor and outdoor, and check continuity on fuses |

| A2 Error | Hardware error of transmission processor (Lossnay). check comms wiring, possible Lossnay board fault | Error is detected when the waveform is transformed on transmission wiring. Possible Lossnay board fault. | Check comms wiring. |

Mitsubishi Air Conditioner Error Codes “F Series”

| Code Text | Description | Cause | Check Procedure |

| FA Error | 51CM connector open circuit. | A thermal relay is an open circuit | Check the thermal relay for disconnection or contact failure, possible defective board |

| F8 Error | No input was detected at the outdoor unit. | The outdoor board is defective. | Check mains power is ok. |

| F9 Error | Both High and Low-pressure switch open the circuit | Both high-pressure and low-pressure switches open the circuit or are incorrectly connected to the control board. Possible control board fault. | Check continuity through both switches and make sure the connections onto the board are secure. Make sure there is no damage to the cables connecting the switches to the board |

| UF Error | Compressor over-current fault.

High current detected within 30 seconds after compressor starts. |

Possible issues with the compressor such as compressor lock or winding failure,

Inverter board or inverter output failure, Faulty wiring between compressor and inverter board, Mains power supply incorrect, Blockage in the refrigerant circuit or stop valve closed |

Measure compressor winding resistance for a dead short/open circuit,

Carry out an inverter output test*, Check compressor wiring for damage, Test for correct mains voltage supply, Ensure the compressor is not trying to pump against a blockage/restriction in the refrigerant circuit |

| EF Error | Non-defined error code. | Noise interference. | Power down the system for 30 seconds and then switch back on. |

| F3 Error | Low-pressure switch open circuit or incorrect contact with the control board | Low-pressure switch detecting low refrigerant pressure in the outdoor unit or the contact of the switch has become disconnected/damaged | Check continuity through the low-pressure switch and connection onto the board, check refrigerant gas pressure or use SW2 dips to check T63HS |

| F7 Error | Phase detection circuit fault. | The power supply phase was reversed. | Check the power supply and swap two phases off. |

| UF Error | Compressor over current fault/ Power board issue | Compressor drawing too much current whilst operating, compressor seized/failed, power board outputting incorrect voltage. | Carry out an inverter output test to prove the power board is functioning correctly, monitor the current draw from the compressor during operation and make sure the compressor is pumping |

| F9 Error | Two or more protection devices are open circuits. | Contact failure of two components. | Check protection devices for disconnection or contact failure. |

| EF Error | Non-defined error code. | Noise interference in the outdoor unit. | Power down Ecodan for 30 seconds

then switch it back on. |

Mitsubishi Air Conditioner Error Codes “P Series”

| Code Text | Description | Cause | Check Procedure |

| P6 Error | Overheating at the heat exchanger. | Lack of water flow, the air in the system, flow rate incorrectly set, blockage, or pump problem. | Check the flow rate is correct for the outdoor unit and bleed any air out of the system. |

| P1 Error | Room sensor fault. | Faulty thermistor, loose wiring connection on the PCB, or sensor setting incorrect. | Check the thermistor for short or open circuits, and check the wiring connection. Check settings in the main controller, Initial settings>Room sensor settings> Sensor settings>Sensor setting, then change the sensing point from TH1 to main R/C or Room R/C depending on what type of thermostat you are using. |

| P9 Error | TH5 Fault. | TH5 is not connected, short or open circuit, also the FTC is not configured for heating only. | Check TH5 is connected correctly. |

| PA Error | Drain Fault.

The indoor unit detects high condensate levels before the unit has started running. |

Float switch activated by high water level. If the unit has a drain sensor then the resistance of the drain sensor has changed due to being immersed in water. | Check the water level in the drip tray – If full, then check the drain pump operation, blockage in the drain pipe, and/or sludge or debris in the drip tray block the ing drain pump intake.

If the drip tray is empty, investigate why the unit believes it is full of water. Test the float switch for correct movement and measure continuity through the switch – open contact when OK and closed contact when in alarm. If the unit has a drain sensor instead of a float then test for correct resistance. Also, a check fault has not been generated from an external high-limit switch connected to either CN4F or CN31 on the indoor board. |

| UP Error | Over-current fault. | Over-current detected after 30 seconds of operation. Compressor lock, faulty inverter output. | Carry out an inverter output test, and see how many amps the compressor is pulling when it goes running. |

| P5 Error | High condensate level in the drip tray. | Float switch activated by high water level. If the unit has a drain sensor then the resistance of the drain sensor has changed due to being immersed in water. | Check the water level in the drip tray and check to see if the float switch is a closed circuit. If the unit has a drain sensor then check the resistance of the drain sensor. |

| P8 Error | No temperature change at the plate heat exchanger. | Problems with the flow rate (too high), incorrect sizing of the system, and problems with the outdoor unit. | Check flow rate, temperature differences across the flow and return, and temps in the outdoor unit using SW2. |

| P9 Error | Indoor Pipe/coil thermistor fault (TH5).

PCB detects incorrect temperature reading from the thermistor. |

Faulty thermistor – dead short/open circuit.

Damaged thermistor cable or poor connection to PCB. PCB incorrectly reading thermistor value. |

Check the connection of the thermistor on the PCB and thermistor wiring.

Unplug the thermistor and test the resistance value – the correct reading can be determined using Thermistor Value Look Up in the app. The thermistor temperature type is ‘NORMAL’. If all the above are correct then replace the PCB. |

| P8 Error | No temperature change in the outdoor unit after 10 minutes of operation. | The temperature difference between the Pressure Transducer (T63Hs), the Inlet water Temp (TH32), the HEX Liquid Pipe Temp (TH6), and the Ambient Temp (TH7) is less than or equal to 2c. | Check for the correct flow rate. Check the correct positioning of all thermistors. Use SW2 on the outdoor unit control board to check the sensor readings. |

| P3 Error | System transmission error. | Communication fault between indoor units. | Possible comms fault between I/C and R/C could also be incorrect group or master/slave settings (check CN40, SW2, and SW6) |

Mitsubishi Air Conditioner Error Codes “U Series”

| Code Text | Description | Cause | Check Procedure |

| UL Error | 63L open circuit. | The low-pressure switch is an open circuit. | Check the continuity of 63L and check the connection on the board. |

| U2 Error | Ecodan High compressor discharge temperature | Discharge thermistor detecting abnormally high temperature during operation. Possible refrigerant leak or water flow issue. Also, check the dip switches are set correctly on the Ecodan unit | Use the SW2 dip switches on the Ecodan to read the discharge thermistor value and T63HS reading, and check airflow through the coil on the Ecodan, and water flow rate. Confirm the dip switches are set correctly on the Ecodan |

| UL Error | Low-Pressure Fault.

– R407c system: Low-pressure switch (63L) activated. – R410a system: No temperature difference detected between outdoor thermistors |

Possible refrigerant leak. Restriction or blockage in refrigerant circuit causing low side pressure to drop. Problem with the pressure switch or the mounting position of outdoor thermistors. | Check the system standing pressure for a complete gas loss. Check the system running pressures/temperatures to determine if the system is short of gas or if there is a restriction/blockage in the circuit – a restriction may show frosting where refrigerant expands – a blockage will show an increase in the high side and a drop on the low side.

R407c system: The low-pressure switch (63L) should be a normally open contact – Measure the switch for continuity, if the correct gas charge is present and the switch stays open contact then replace the switch. R410a system: Check thermistors are connected correctly to the pipework |

| UF Error | Compressor over-current fault.

High current detected within 30 seconds after compressor starts. |

Possible issues with the compressor such as compressor lock or winding failure,

Inverter board or inverter output failure, Faulty wiring between compressor and inverter board, Mains power supply incorrect, Blockage in the refrigerant circuit or stop valve closed |

Measure compressor winding resistance for a dead short/open circuit,

Carry out an inverter output test*, Check compressor wiring for damage, Test for correct mains voltage supply, Ensure the compressor is not trying to pump against a blockage/restriction in the refrigerant circuit |

| U1 Error | Ecodan High-pressure fault | Usually caused by abnormal water flow on the primary circuit. | Check the flow rate on the flow setter/sensor, check the operation of pumps and zone valves, check the water pressure and air in the primary water circuit |

| UP Error | Over-current fault. | Over-current detected after 30 seconds of operation. Compressor lock, faulty inverter output. | Carry out an inverter output test, and see how many amps the compressor is pulling when it goes running. |

| U4 Error | Ecodan unit thermistor fault | TH3/TH32/TH6/TH7/TH8 thermistor reading abnormal temperature value | Check resistance through thermistors and connection onto the board, use SW2 dip switches to check temperature readings |

| U6 Error | Over-current fault

Inverter board abnormality when over-current is detected |

Possible issues with the compressor such as compressor winding failure,

Inverter board or inverter output failure, Faulty wiring between the compressor and inverter board, Mains power supply is incorrect. |

Measure compressor winding resistance for a dead short/open circuit,

Carry out an inverter output test, Check compressor wiring for damage, Test for correct mains voltage supply. |

| U8 Error | Outdoor Fan Motor related issue | The fan motor seized or not operating correctly, the incorrect voltage from the control board to the fan motor, F5 fuse blown on the control board | Check fan motor rotation and resistance, test the voltage output of the control board on the fan connection, check continuity through the F5 fuse, and make sure the fan blade is not damaged or catching on any other component within the unit |

| U1 Error | HIGH-PRESSURE FAULT | A high-pressure switch (63H) activates during unit operation. | First, check for the correct flow rate on the flow setter. Check for any problems with water circulation such as pump failure, airlocks, or blockages. or Check for continuity on the high-pressure switch |

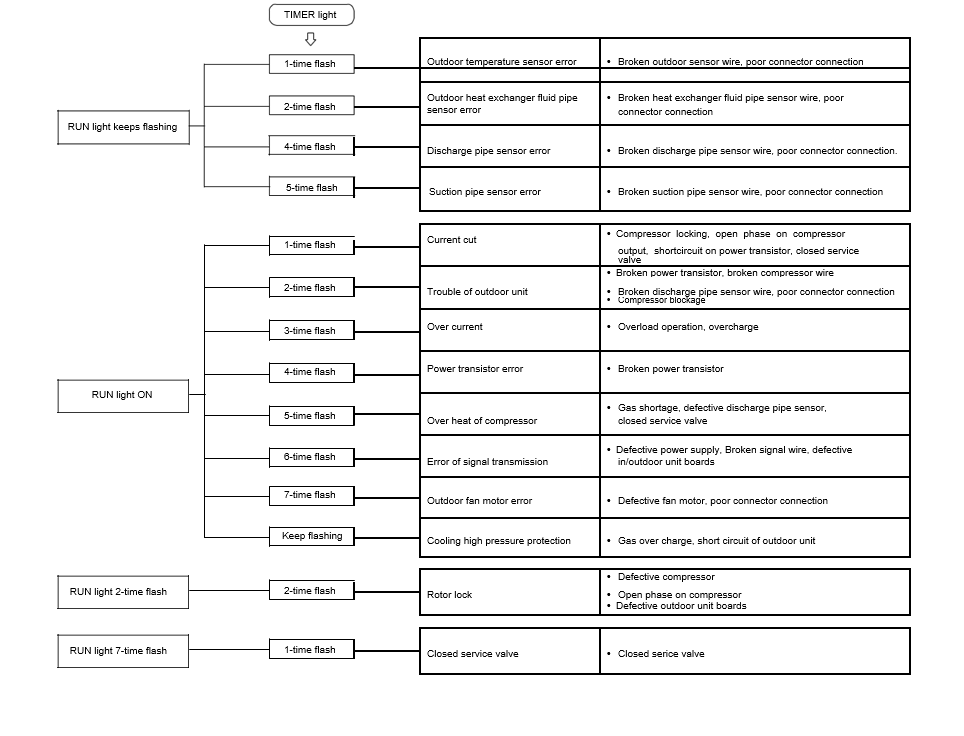

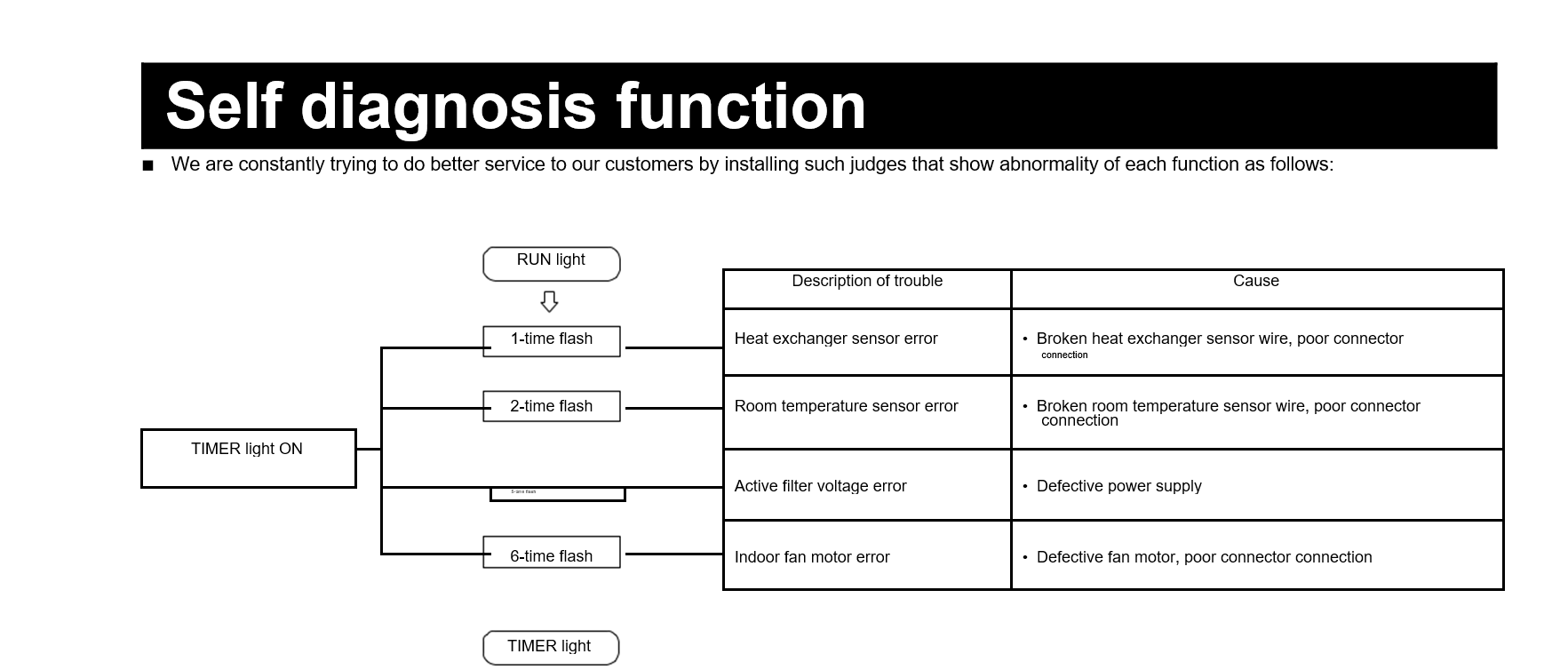

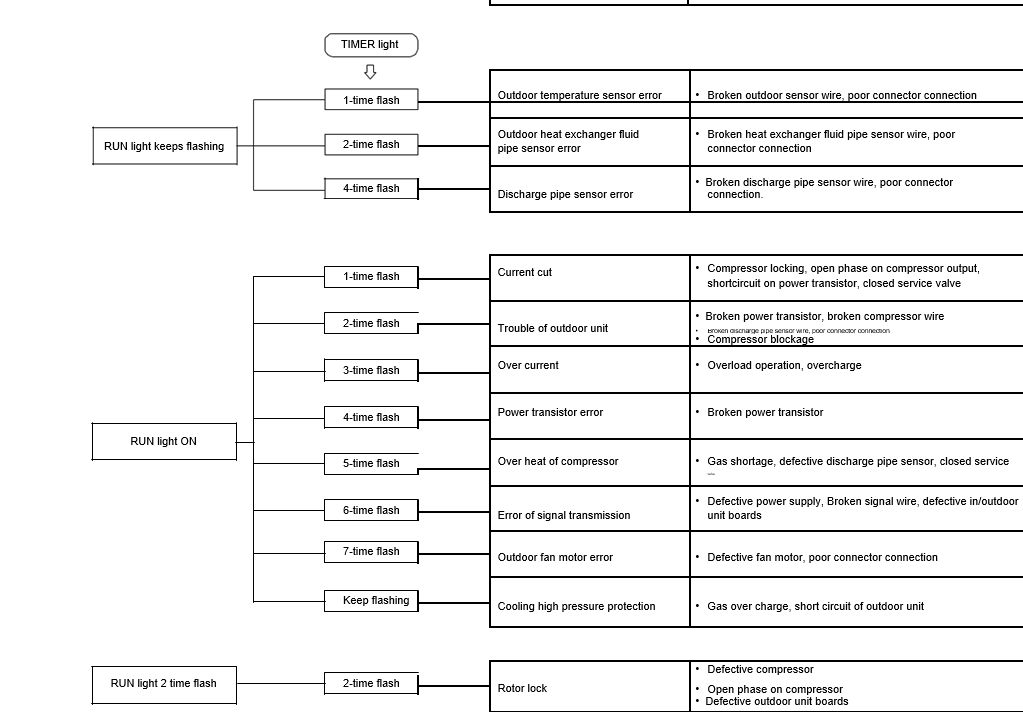

Mitsubishi LED Blinking Troubleshooting Guide

| Error Codes | Problems |

| LED- E0 | Transmitting/receiving signal error |

| LED- P1 | Intake air sensor problem |

| LED- P2 | Pipe sensor problem |

| LED- P4 | Drain sensor problem |

| LED- P5 | Malfunctioning of the drain overflow protecting mechanism |

| LED- P6 | Problems with the coil frost/overheating protection mode |

| LED- P3 | System error (transmitting/receiving signal) |

| LED- P7 | System error (address) |

| LED- P8 | Outdoor unit malfunction |

| Mr.Slim K-control | PUH-EK Outdoor unit |

| LED- ON | Operation status |

| LED- Flash | Check code display |

| LED- LD1 | LED- ON Compressor directive LED- Flash Reverse phase detect |

| LED- LD2 | LED- ON Heating directive LED- Flash Open phase detect |

| LED- LD3 | LED- ON During 63H1 operation LED- Flash Pipe sensor short/open |

| LED- LD4 | LED- ON Compressor ON LED- Flash High-pressure switch (63H2) operation |

| LED- LD5 | LED- ON Outdoor fan ON LED- Flash Over current relay (51CM) operation |

| LED- LD6 | LED- ON 4-way valve ON LED- Flash Thermal switch (26C) operation |

| LED- LD7 | LED- ON Bypass valve ON LED- Flash Thermistor (TH3) overheat protection |

| LED- LD8 | LED- ON Crankcase heater ON LED- Flash Defective input |

Mitsubishi Air Conditioner Error Codes Numerical

| Error Codes | Problem | Troubleshooting |

| 0403 Error Code | Serial communication error | Test the wiring between the main board and the inverter board. |

| 0900 Error Code | Test run | Test Dipswitch SW2-1 on the main control board. |

| 1102 Error Code | Discharge temperature prob. | Test the compressor’s running current. |

| 1301 Error Code | Low-pressure prob. | Test the system standing pressure for gas loss |

| 1302 Error Code | High-pressure prob. | Test for clogged filters or restricted coils. |

| 1500 Error Code | Refrigerant overcharge | Test for the excess refrigerant returning to the ODU through overcharging. |

| 2500 Error Code | Drain sensor submerge | Test the water pump and water flow rate. |

| 2502 Error Code | Drain pump prob. | Test the float switch for continuity. |

| 2503 Error Code | Drain sensor prob. | Test for a short circuit and replace the sensor if damaged. |

| 2600 Error Code | Water leakage | Test for water leakage on humidifier pipes. |

| 4102 Error Code | Open phase | Test power supply, wiring, and fuses. |

| 4106 Error Code | Transmission power supply prob. | Test wiring, input voltage, and broadband connection. |

| 4115 Error Code | Power supply signal sync error | Test mains power, fuses, and PCB connections. |

| 4116 Error Code | Motor/RPM error | Test the fan motor connections, confirm secure fixing, clear the debris, or replace the motor/circuit board. |

| 4220 Error Code | Abnormal bus voltage | Test mains supply and DC bus voltage. |

| 4225 Error Code | Low bus voltage | Test mains power and voltage at the diode stack. |

| 4230 Error Code | Heatsink overheat protection | Test for blockages in the air passage, inverter failure, or inverter fan prob. |

| 4240 Error Code | Overload protection | Test inverter balance and reduce airflow through the heat sink. |

| 4250 Error Code | Over current protection | Test for open and short circuits and repair them. |

| 4255 Error Code | Outdoor fan error | Test the voltage on the fan and motor windings for short circuits. |

| 4260 Error Code | Heatsink overheat protection at start-up | Replace the THHS thermistor if faulty. |

| 5101 Error Code | Temperature sensor prob. | Test for prob. address code, thermistor connections, and wiring. Otherwise, replace the PCB. |

| 5102 Error Code | Return air thermistor prob. | Test for connection issues and thermistor resistance and replace the sensors or circuit board. |

| 5110 Error Code | Outdoor inverter heatsinks thermistor error | Test for open/short circuits and disconnections from the PCB. |

| 5201 Error Code | Pressure sensor failure | Reconnect or replace the sensors. |

| 5301 Error Code | Current sensor failure | Replace the sensors if faulty |

| 5701 Error Code | Loose float switch connector | Test for correct float switch operations and external pumps. |

| 6201 Error Code | Remote controller issue | Replace the remote controller. |

| 6600 Error Code | Address overlap | Match the address with the broadband network. |

| 6601 Error Code | Polarity setting issue | Test for voltage issues and cable sizes. |

| 6602 Error Code | Transmission procedure hardware error | Test the controller and broadband connections, and replace the circuit board if required. |

| 6603 Error Code | Transmission line bus busy error | Test for faulty wiring and repair it. |

| 6606 Error Code | Communication failure | Test the PCB for defects. Reset the power. If the error persists, replace the PCB. |

| 6607 Error Code | No ACK error | Test for power supply, Loss nay address, cable length, and termination. |

| 6608 Error Code | No response error | Test and repair cable termination, length, and type of cables used. |

| 6831 Error Code | MA controller signal reception error | Test the remote, cable length, types of cable and connections. |

| 6832 Error Code | MA controller comms prob. | Test remote, cable length, types of cable used, and connections. |

| 6833 Error Code | MA controller comms prob. | Test error code 6832 solution |

| 6834 Error Code | MA controller signal reception error | Test error code 6832 solution |

| 7100 Error Code | Total capacity error | Add capacities of all indoor units and match them with the outdoor unit capacity. |

| 7101 Error Code | Capacity code setting error | Test for capacity dips in IDU and ODU. |

| 7102 Error Code | Wrong number of connected units | Test for voltage on the broadband set-top box and if you have connected the correct box. |

| 7105 Error Code | Address setting error | Test the address setting on the OC and BC. |

| 7106 Error Code | Attribute setting error | Ensure that the SW3-1 setting is on. |

| 7110 Error Code | Signal transmission error | Test for broadband connections. |

| 7111 Error Code | Remote controller sensor prob. | Test SW-1 on the IDU. |

| 7113 Error Code | Function setting error | Test the SW5-10 settings and SW6 settings. |

| 7117 Error Code | Model setting error | Test the dips, resistors, and thermistors. |

| 7130 Error Code | Incompatible unit combination | Test broadband wiring on the systems. |

Conclusion

In conclusion, a Mitsubishi air conditioner is a valuable investment for keeping your home comfortable during the hot summer months. However, even the best air conditioners can develop problems over time. Following the troubleshooting guide outlined in this blog, you can identify and potentially solve common issues with your Mitsubishi air conditioner.

Remember to exercise caution when attempting to diagnose or repair your air conditioner and seek professional help if necessary. Hope this Mitsubishi air conditioner error codes list and troubleshooting guide helps you and you find out the solution. thanks!

Read More-

Why Is My Air Conditioner Hissing?

Does Running the Fan on My Air Conditioner Reduce Humidity?

How to Fix E4 Error In Gree Air Conditioner

E5 Gree AC Error Code Troubleshooting